|

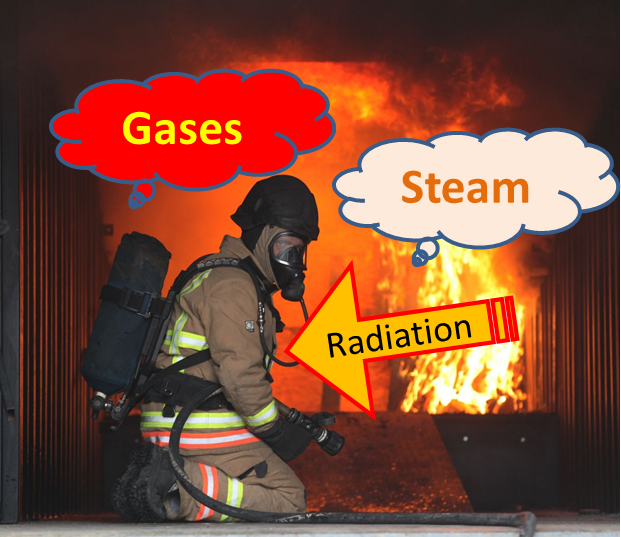

How and where to measure the temperature? Globe gas and radiation combined temperature thermometer. Using the combined temperature measurement from inside the ball and the gas temperature measurement from the exposed thermometer, a better idea of the temperatures personnel are experiencing can be made. The Benrhos Globe thermometer is designed to measure the combination of the temperature of gases and the effect of thermal radiation experienced by fire fighters during training and workers in a hot processing environment. From our experience the thermometers used in live fire training facilities do not measure the true temperature on those near the fire. This is mainly due to 4 reasons:

The Combi thermometer is a development based on having a black ball that is about the size of parts of a human that are likely to get too hot, such as a hand or the back of the neck. The ball is coated in a high emissivity coating so it absorbs most of the radiant heat that impinges on it. Inside the ball is a fast response thermometer that measures the combined effect of the radiation and the local gas temperature to give a truer indication of what personnel would be experiencing. Attached close to the ball is another fast response thermometer that measures the gas temperature. Its job is to pick up any rapidly changing temperature such as a steam surge. The temperatures can be displayed locally or transmitted via WiFi to remote locations.

0 Comments

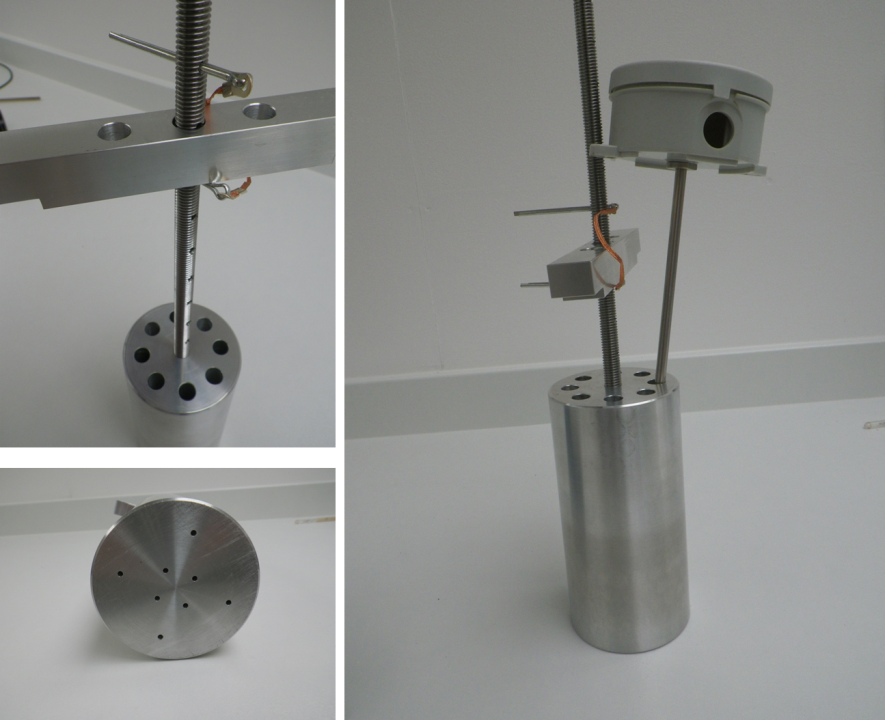

Benrhos can help design and produce accessories for calibration laboratories such as the aluminium insert for a Fluke liquid calibration bath shown below. Most materials can be machined including deep hole drilling of metals such as nickel alloys and Fecralloy. Inserts for Isotech, Ametek and Fluke baths can be supplied to the customer's requirements at a competitive price. The bath insert example above has:

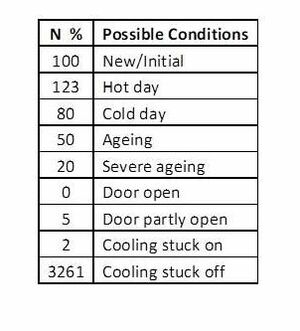

We have been working on simplifying the condition monitoring of fridges and freezers; with just a few non-intrusive measurements plus a calculation we can alarm the conditions shown below based on a tolerance of say being above 150% or below 30%.

The alarm could be simply displayed or sounded locally with the option of exporting it to a monitoring system if required. As it is so simple and non-intrusive it has the potential of being extremely cost effective. Contact: info@benrhos.co.uk |

Archives

May 2019

Categories |

Our Services |

Company |

Copyright 2023 Benrhos Ltd: Tyn Y Benrhos, Llanfachreth, Dolgellau, LL40 2NW: info@benrhos.co.uk

RSS Feed

RSS Feed